Mitsubishi Electric Corporation - Experts & Thought Leaders

Latest Mitsubishi Electric Corporation news & announcements

Berkshire-based mechanical and electrical engineering firm, Campbell West, has completed a major transformation at Hertfordshire University in Hatfield. The five-month project formed part of a wider renovation project by Carmelcrest at the University’s School of Creative Arts. The works included a complete overhaul of the building’s heating, ventilation, and air-conditioning (HVAC) infrastructure, as well as the refurbishment of the male, female, and disabled WC facilities. Air quality and comfort Commenting on the project, Steven Campbell, co-founder and director of Campbell West, said: “We are proud to have been able to play a key role in such a major refurbishment project for Hertfordshire University." "The transformation is significant and will make a big impact on the functionality of the space, the air quality, and comfort for the students and staff using the building.” Climate control across multiple zones Mitsubishi VRV system, comprising 23 fan coil units, was installed to provide effective climate control The HVAC solution provided by Campbell West was extensive and included the installation of three Swegon air handling units, to ensure efficient ventilation and air quality throughout the building. In addition, a Mitsubishi VRV system comprising 23 fan coil units was installed to provide effective climate control across multiple zones. Final outcome of the project Michael Timmons, project manager at Campbell West who took the lead on the Hertfordshire University project, added: “We are really pleased with the final outcome of this project, which has delivered much improved facilities for those using the space." "Our success is down to the commitment and expertise of our team, and ability to co-ordinate effectively with the multiple trades working on the project.” Campbell West industrial buildings Campbell West was originally founded in 2017 by Steven Campbell and Daniel West, who met while working together as apprentices. With an initial focus on the healthcare sector, the company has expanded its reach to other industries including local government, education settings, data centers, workspaces and industrial buildings, plus large residential projects.

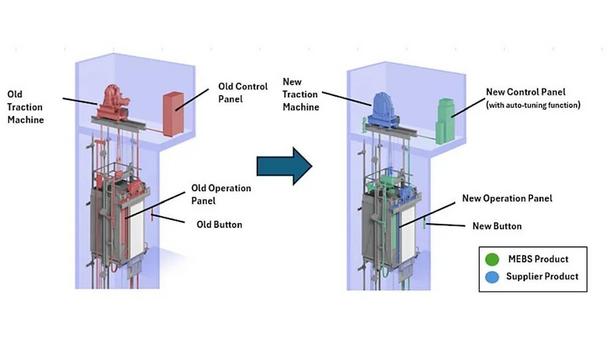

Mitsubishi Electric Building Solutions Corporation (MEBS, Head Office: Chiyoda-Ku, Tokyo; President: Iwao Oda) announced the launch scheduled for 19 March of a new overseas control renewal menu for elevators made by other companies installed in existing buildings. By developing a new control panel with an auto-tuning function, MEBS will respond to the diverse needs of its overseas customers for the renewal of control systems for elevators, while spurring the expansion of its maintenance and renewal business. Main Features of Renewal Menu 1) Achieving control that maximizes ride comfort even with other companies' traction machines through auto-tuning It is possible to upgrade to the latest control system by utilizing an MEBS control panel together with a traction machine made by another company. The newly developed control panel equipped with an auto-tuning function estimates the characteristics of the other company’s traction machine and automatically derives the control parameters for the combination of the other company’s traction machine and the MEBS control panel. This eliminates the need to develop a dedicated control panel for the traction machine and improves ride comfort. 2) Improving safety and contributing to sustainability by promoting the renewal of existing elevators The renewal menu promotes the renewal of existing elevators to improve safety and convenience, and contributes to sustainability by reducing power consumption and waste emissions through the reuse of some of the equipment. The menu also reduces downtime by eliminating the need to replace all of the equipment. 3) Achieving improved convenience in response to diversifying building solution needs By adopting the renewal menu, it is possible to introduce integrated building solutions utilizing MEBS’s unique technologies such as the global remote-maintenance service M’s BRIDGE, DOAS (Destination Oriented Allocation System, elevator coordination with mobile robots, Elevator Call System with Smartphone, and BMS (Building Management System). Elevator parts manufacturers MEBS receives numerous requests from customers with existing elevators In the overseas elevator market, there are many elevator parts manufacturers and specialized elevator maintenance companies that respond to diverse customer needs. With such a wide variety of choices available, MEBS receives numerous requests from customers with existing elevators made by other companies to provide them with higher-quality services by renewing their control systems using the control panels. MEBS’s newly developed control panel Normally, when combining a control panel with a traction machine from a different manufacturer, it is necessary to develop an individual control panel that matches the characteristics of the traction machine. However, by adopting MEBS’s newly developed control panel equipped with an autotuning function, there is no need to develop a dedicated control panel for each traction machine, and the latest control technology can be introduced while utilizing other companies’ traction machines. New autotuning function-equipped control panel The control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators As a result, performance can be improved while reducing costs and ensuring stable long-term operation. Until now, the control renewal menu has been limited to “ELEMOTION” for existing MEBS elevators, but with this new autotuning function-equipped control panel, they can now offer control renewal for existing elevators made by other companies, which will allow us to meet an even wider variety of customer needs. Outlook MEBS, which is in charge of the building systems business, a key growth area for Mitsubishi Electric, is planning to expand and accelerate the global elevator maintenance and renewal business as a priority strategy. Through this menu, they are aiming to renew 1,000 elevators annually by 2030, mainly in North America and Europe.

Mitsubishi Electric Corporation announced that it has signed an agreement with HD Renewable Energy Co., Ltd., a Taipei-based developer and operator of solar power and battery storage systems, to collaborate on initiatives that will help realize carbon neutrality. As part of their collaboration, the companies will establish an aggregation business joint venture and Mitsubishi Electric will acquire a stake in HD Renewable Energy. Profitability of power generation Amid rising fuel costs and global efforts to realize carbon neutrality, Japan is actively promoting the adoption of renewable energy. However, owing to fluctuations in power generation from renewable sources such as solar and wind resulting from their dependence on seasons, weather, and time of day, transmission system operators are required to continuously monitor the demand for power and fine-tune adjust supply and demand. Against this backdrop, there is an expansion in the aggregation market, where multiple distributed energy resources (DERs), such as renewable energy generation facilities and battery storage systems, are utilized to help stabilize power grids and maximize the profitability of power generation and storage businesses.